- Products

- Installation

- Gluing/Sealing Application

- Tightening Application

- Error - proofing Application

- About Guchi

- Contact Us

- …

- Products

- Installation

- Gluing/Sealing Application

- Tightening Application

- Error - proofing Application

- About Guchi

- Contact Us

- Products

- Installation

- Gluing/Sealing Application

- Tightening Application

- Error - proofing Application

- About Guchi

- Contact Us

- …

- Products

- Installation

- Gluing/Sealing Application

- Tightening Application

- Error - proofing Application

- About Guchi

- Contact Us

"SmartEye" error prevention expert

"Smart Eye" error prevention expert

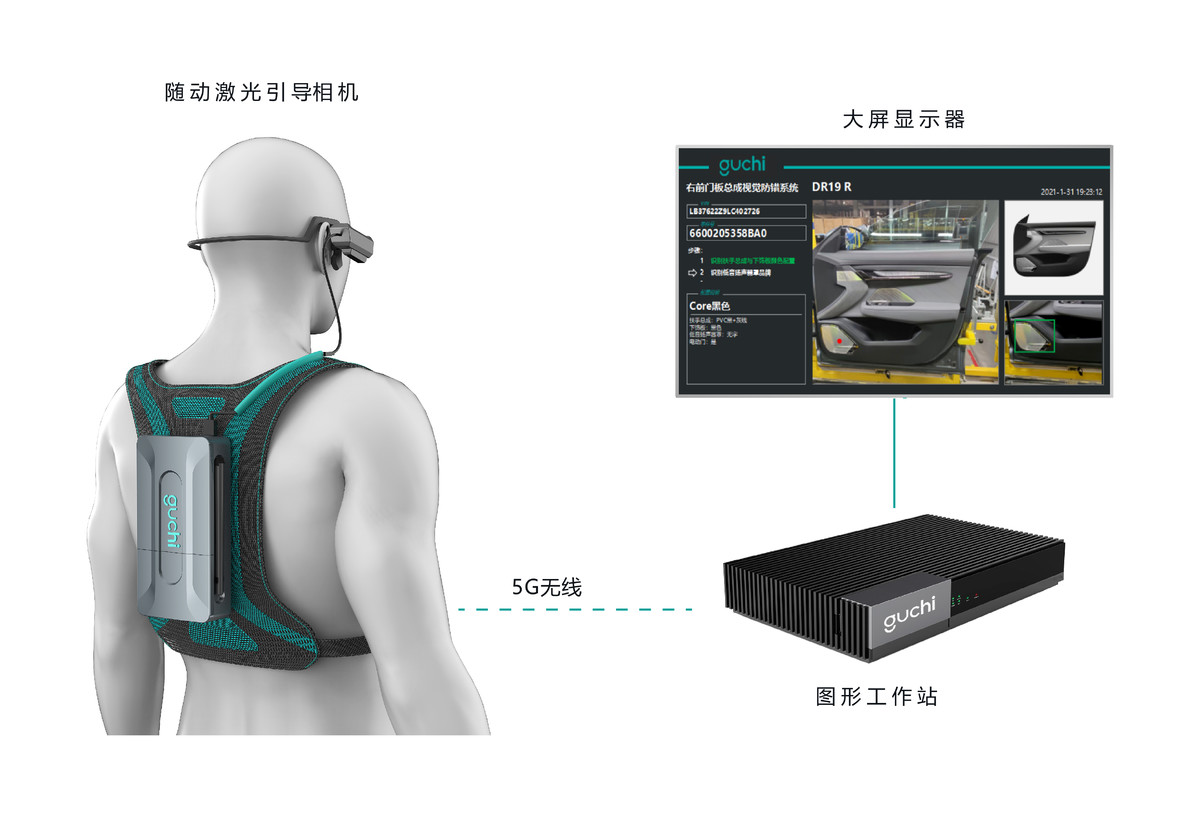

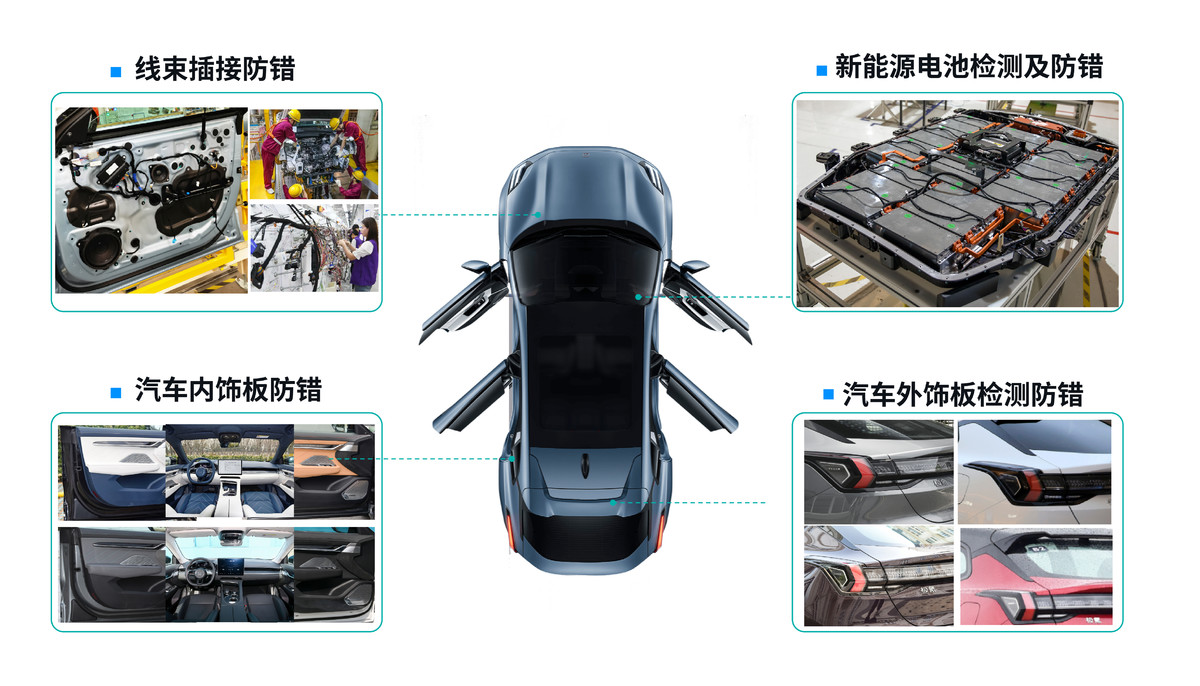

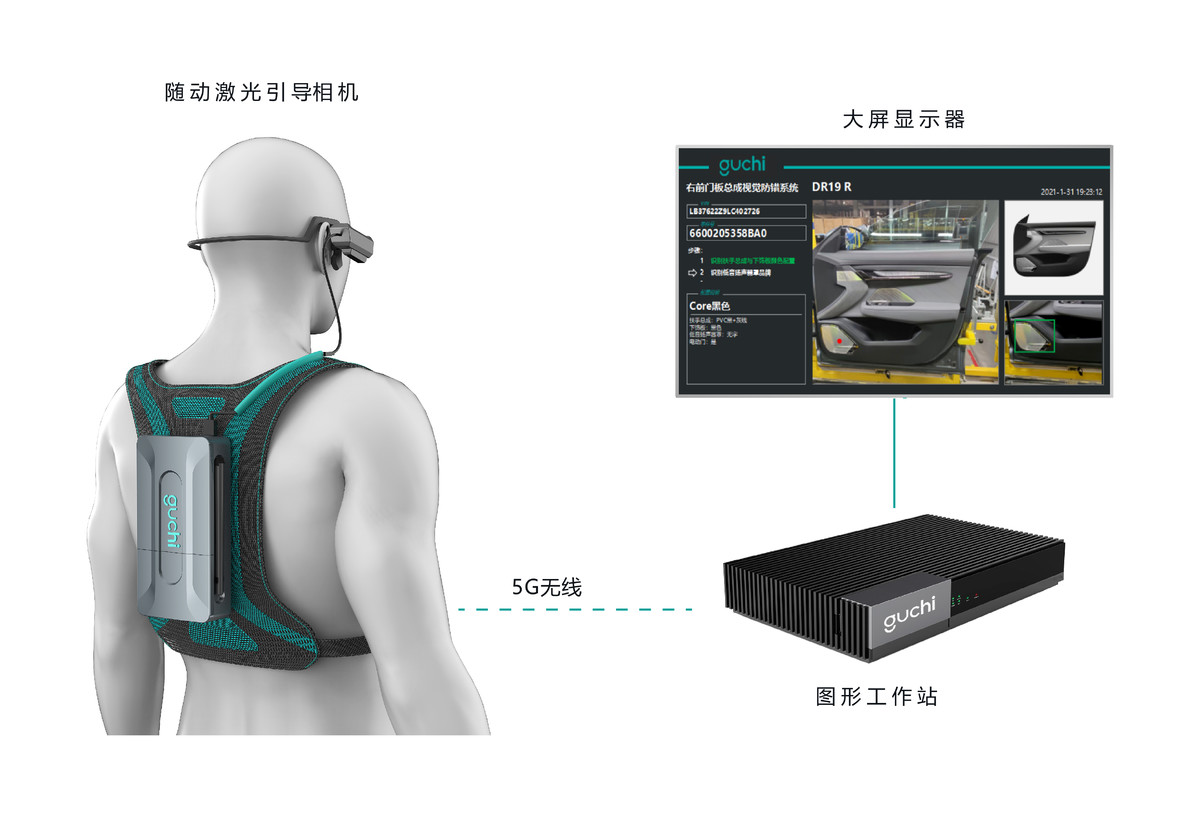

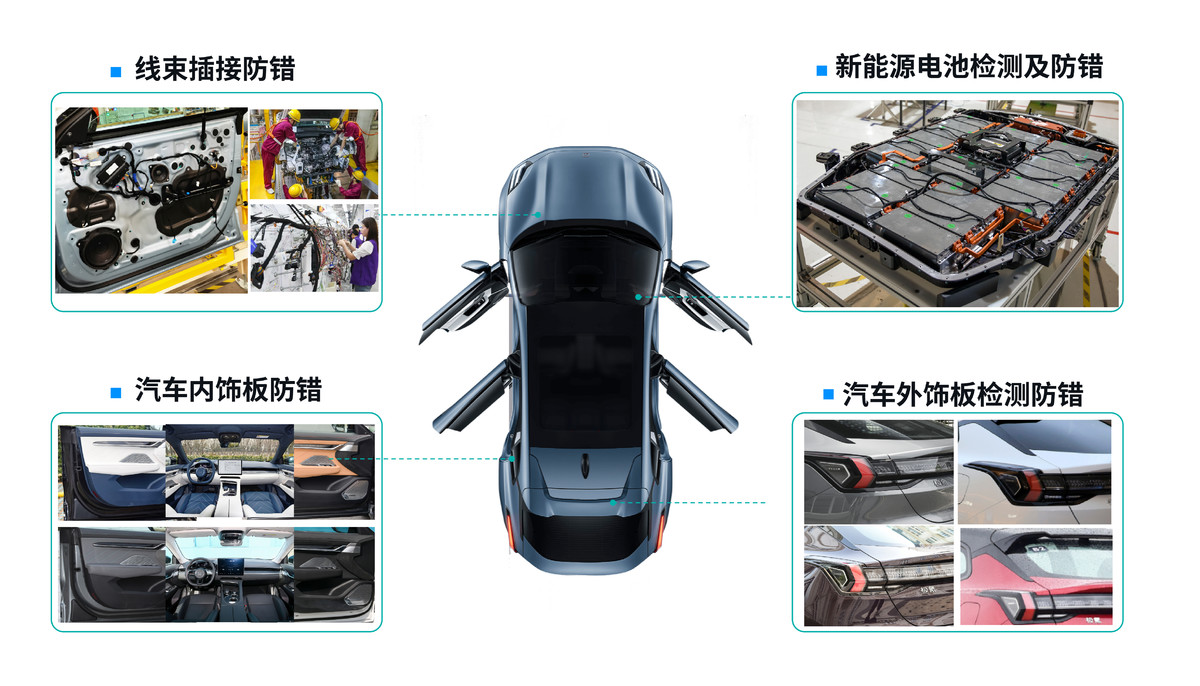

Guchi designed and developed the "Smart Eye" error prevention expert,,which can enhance the perception and analysis ability of assembly personnel in complex assembly scenes. It is mainly suitable for real-time error prevention and detection of mobile-station assembly, it includes fault-proof identification of wiring harness plug-in, defect and leak detection of parts, fault-proof identification of new energy battery field, Operation Instruction and error correction, fault-installation and leak-installation detection, production information recording, rhythm monitoring, etc. , it can be applied to the assembly scenes of passenger cars, commercial vehicles and so on, and can greatly improve the assembly efficiency, assembly quality and assembly success rate of automobiles.

Customer pain points

- Wire harness plug-in error-proof identification

- Missing detection of part defects

- Mobile station error proofing is limited

- New hires take a long time to get started

- Manual inspections are unreliable

- Misfitted/missed

Typical applications

- Cable harness plugging is error-proof

- Operation guidance and error correction

- Interior and exterior error proofing

- Beat monitoring

- Production information records

- Real-time inspection

About Guchi

Contact us

Products

Landline:021-59556007

HR Email:hr@

Sales Telephone: 1 248 318 4583

Sales Mail: sales@